History of trophies

The origin of trophies goes back to ancient Greece, where the tropaion was raised on the battlefield to commemorate victory. Often assembled from captured weapons, it carried both symbolic and religious meaning, acknowledging divine protection. In Roman times the tradition evolved: trophies became more durable honorary objects and were integrated into public ceremonies and displays of power. Over the centuries, the idea of the trophy moved beyond warfare and became associated with games, contests, and athletic competitions. With the rise of modern sport in the 19th century and the revival of the Olympic Games, cups and medals took the familiar form of keepsakes meant to be preserved. Today, trophies represent recognition of effort, merit, and performance, combining historical heritage with design and modern manufacturing.

Manufacturing methods

Metal cups – stamping & plating

Metal cups are commonly formed by stamping or deep drawing from metal sheets, then assembled (handles, base) and finished (polishing, lacquering, plating). Gold, silver, or nickel finishes enhance appearance and help protect the surface.

Plastic injection (PVC) – molded parts

In plastic injection molding (PVC or resins), pellets are heated and injected into a mold under pressure. This enables lightweight, cost-effective shapes at scale, often painted or metallized for a more premium look.

Black or white marble bases

Black or white marble bases are cut, squared, and polished. Fixing holes are drilled for the cup and a nameplate is added. Marble provides weight, stability, and a traditional premium feel.

Glass and crystal trophies

Glass and crystal trophies are cut, beveled, and polished for sharp edges and high clarity. Crystal’s density creates stronger refraction and sparkle, which is why it’s often chosen for high-end awards.

Acrylic trophies

Acrylic is laser-cut or CNC-machined. It’s light, durable, and can be clear, tinted, or printed. It supports modern silhouettes and layered plaque designs.

Personalization techniques

Laser engraving (glass, crystal, acrylic)

Laser engraving personalizes an award by marking the material with a highly focused beam. On glass, crystal, or acrylic, it creates a clean contrast (a frosted or etched effect) without using ink. Names, dates, and detailed logos can be reproduced consistently across multiple pieces. The finish is long-lasting, remains readable after handling, and is widely used for commemorative and institutional trophies where durability and precision matter.

Sublimation (plate or insert)

Sublimation is a heat-transfer method commonly used for coated plates and inserts. Under high temperature, the ink turns into gas and bonds with the coating, enabling full-color graphics, gradients, and even photo-like designs. It is valued for rich color reproduction and reliable everyday resistance on compatible materials. Sublimation is a strong option when you want vivid, multi-color artwork on a prepared surface.

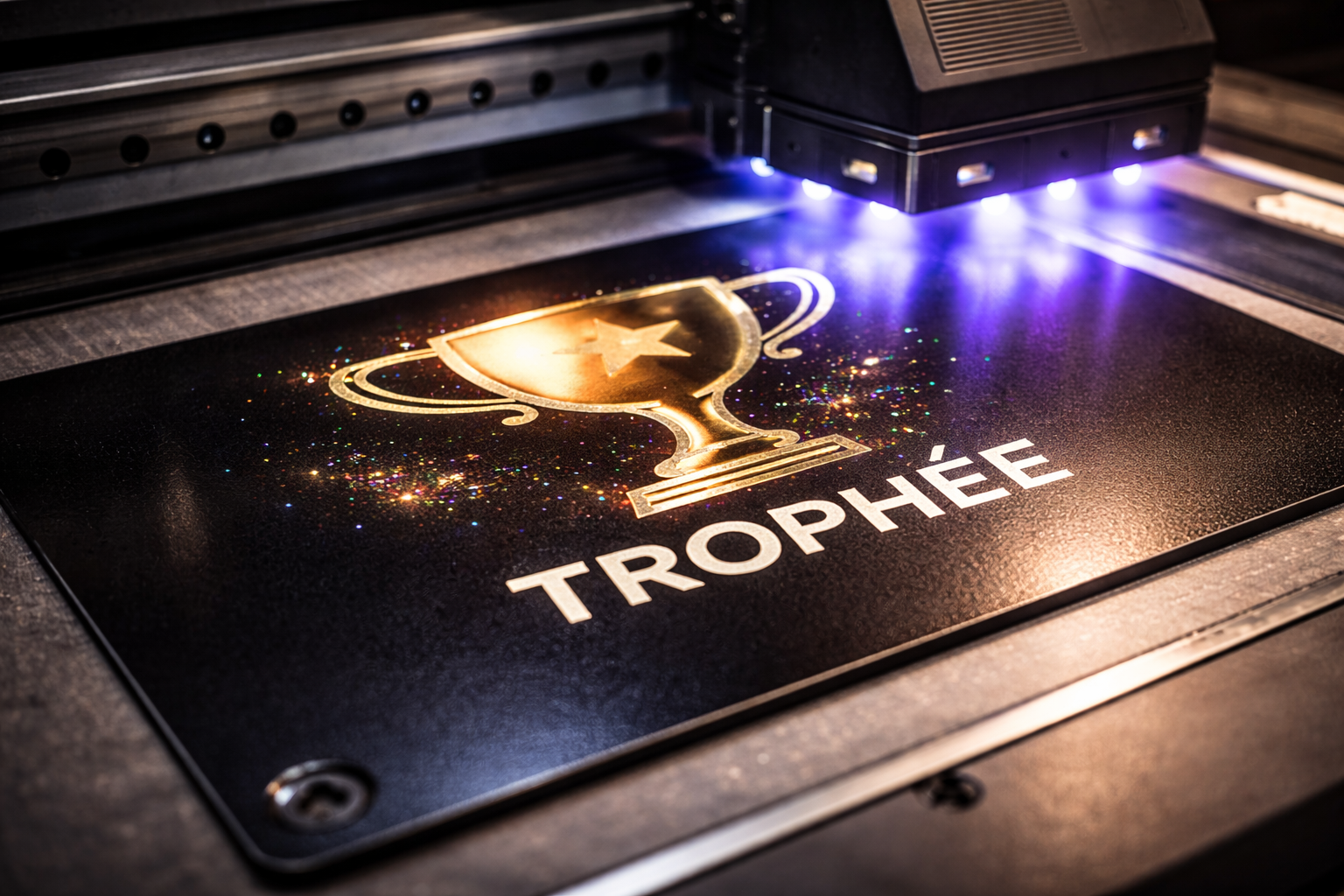

UV flatbed printing

UV flatbed printing applies ink directly onto the surface and cures it instantly with ultraviolet light. This allows detailed, full-color logos and artwork on rigid substrates such as acrylic, metal, and—depending on preparation—glass. Key advantages are design freedom, sharp detail, and good durability. For best results, adhesion and surface preparation are matched to the chosen material and the expected handling conditions.

Mechanical rotary engraving

Mechanical rotary engraving removes material with a cutting tool to create recessed lettering. On metal or rigid plastics, it produces a classic, long-lasting look and very readable markings. Depending on the desired style, the engraved area can be left natural or color-filled as an option. This robust method is frequently used for nameplates, traditional cups, and awards that require a timeless engraved finish.

Trophies by city (Switzerland)

Zurich | Geneva | Bern | Basel | Lucerne | Lausanne | Fribourg | Neuchâtel | Lugano

Sources & references

Order

For personalized trophies, cups and medals in Switzerland (Zurich, Geneva, Bern and more), you can order from our partner TopTrophy Sàrl.